PAT technologies, bioprocess analysis, CFD and statistical modeling, chemometrics, process sensor technology, control engineering

Group leader: Dipl.-Ing. Dominik Ulrich Geier

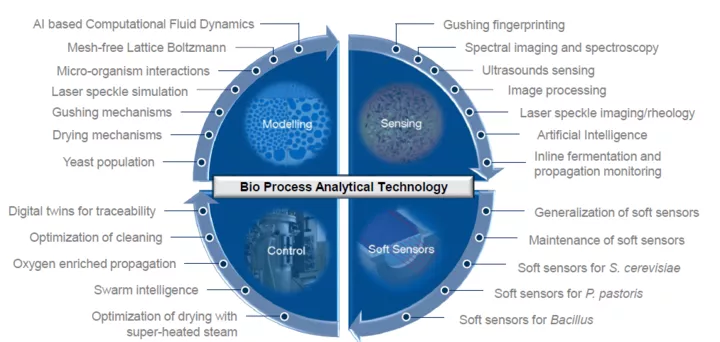

The BioPAT and Digitization working group deals with issues in the fields of PAT technologies, bioprocess analysis, CFD and statistical modeling, chemometrics, control engineering, artificial intelligence, soft sensors and process sensor technology. In the field of process sensor technology, a special focus is on the application and further development of ultrasound, imaging systems and spectroscopy. Areas of application for research are in particular beverage production, white biotechnology and bakery production.

CURRENT PROJECTS

Pichia model process – Knowledge-based process intelligence – new paths to stable bioprocesses

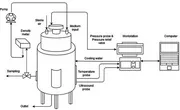

As part of the strategic alliance "Knowledge-based process intelligence - New paths to stable bioprocesses" (2014 to 2021), partners from industry and science are developing a multimodal sensor and software platform for the monitoring and control of biotechnological processes. A biotechnological model process (pilot scale in 30 L and 15 L bioreactors) for the cultivation of the methylotrophic yeast Pichia pastoris for the production of a recombinant protein was established at the Chair of Brewing and Beverage Technology. In close cooperation with partners from the biotechnological and food technology industries, soft sensors for predicting process variables that cannot be measured directly online, concepts for sensor network monitoring and intelligent control approaches (e.g. fuzzy control) are being developed. Contact

Thermal drying processes are monitored by the use of thermography. Thus, for example, inhomogeneities in the dry material can be detected and the process can be optimized based on this information. Contact

The automation of a process for complete monitoring and autonomous control is a high investment. By the coupling of novel soft sensors with multivariate process control, processes can be monitored cost-efficiently and an intelligent control system can be developed. Contact

The aim is to increase the efficiency of industrial Bacillus spp. bioprocesses for the production of enzymes using soft sensors and knowledge-based control strategies. For this purpose, data-driven, mechanistic, but also hybrid concepts are executed and implemented in the higher-level process monitoring. Contact

Soft sensors for key variables of biotechnological processes have so far been developed purely process-specifically under high effort. In this context, approaches are being researched that will ultimately enable automated and standardized soft sensor development. Continuous learning of the soft sensor model (model maintenance) and generalizability are in the focus. Contact

Oxygen is a limiting factor in many yeasts fermentation processes. To improve the oxygen supply during fermentations, a membrane-based method for oxygen enrichment of the feed air is being investigated. This method will be implemented in a control system to optimize the performance of fermentations. Contact

A central process step in the production of cereal-based bakery products is the kneading process, as errors that already occur during dough production have an effect through to the end product. In the course of the research project, the surface properties of the dough are detected by laser scattering and from this the rheological characteristics are determined in real time using a developed model. Contact

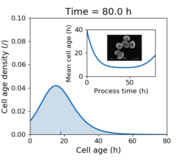

Classical models of microbial growth assume a homogenized representation of the underlying cells. By developing population models, the heterogeneity of a cell population can be taken into account, thus creating the basis for improved yeast management systems. Contact

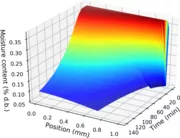

The drying of food is typically associated with large volume changes, which are proportional to the reduction in water content. Mathematical models for moisture transport and rheological behaviour can be used to design new process control strategies that take into account the mechanical behavior of the dried product. Contact

The aim of this research study is to simulate the temporally and spatially resolved light intensity and the behaviour of fluctuating particles. This is done with the Fluctuating Lattice Boltzmann Method (FLBM), which is coupled with the simulation of the radiative transfer equation. The simulation results are used to optimize the design of laser measurement systems for various applications. Contact

The aim of this research is to develop a microscopic model that considers biological, chemical, and mechanical processes to predict the interaction of microorganisms in the biological systems. Therefore, it provides a „bottom-up“ prediction model that will be ultimately used to optimize the process. The simulations are performed under different initial conditions of substrate concentration, pH, and temperature to generate data-sets which will be used to construct a prediction model. Contact

The Lattice Boltzmann Method is a powerful simulation tool for computational fluid dynamics and related phenomena including heat and mass transfer. While the standard LBM relies on a square Cartesian grid in space, it can be beneficial to formulate LBM methods for irregular grids or point clouds. This allows the usage of higher-order lattices without defects in Galilean invariance, higher-order spatial discretization and smooth variation in grid density near walls and flow obstacles. Using the least squares method or radial basis functions nodal variants of LBM were developed, which only require scattered nodes and minimal adjacency information. Contact

Artificial intelligence (AI) is able to learn and analyze nonlinear complex dependencies between high-dimensional variables. The main goal of this project is the development and training of a multi-layer neural network, which is able to analyze fluid dynamics based on CFD data. The applications include feature extraction using the underlying physical laws of fluid dynamics as well as product optimization. This methodology can be applied to a wide range of CFD problems, especially those that are computationally and time-consuming. Contact

As people's nutritional awareness increases, so does their claim to the quality of food. Some nutritional aspects include a reduced calorie content due to a lower fat or sugar content. Another aspect is the desire of the consumer for more transparency with regard to the production of the food. One way to provide consumers with more transparency in the food consumed is to provide the food with a "Digital Food Passport" that includes all the details related to the production of the food. A prerequisite for a Digital Food Passport is the development of "Digital Twins", which contain all the data of the production facilities, the packaging and the food itself. The aim of the project is to demonstrate the integration of all this data in a semantically structured way along the value chain, with any data analysis or monitoring function being done using cloud-based apps. Contact

Numerical Fluid Simulation in Beverages – Investigations of the underlying mechanisms of gushing in carbonated drinks using the Lattice-Boltzmann simulation

Gushing is a phenomenon that can spontaneously occur in carbonated beverages. The main goal of this research project is to elucidate the physical mechanisms leading to gushing. For this purpose, a multiphase Lattice Boltzmann simulation (LBM) is being developed to examine the complex effects caused by blister nucleation. In addition, these approaches are validated by experimental measurements.Contact

Physical Gushing – Physical studies on bubble germ stability and bubble formation during spontaneous foaming of carbonated beverages using optical methods and multivariate modeling to predict the gushing potential

Gushing is the phenomenon of overfoaming upon opening a beer bottle, which cannot be attributed to over-carbonation or mishandling. Fungal proteins known as hydrophobins originating from infected malt have been suggested as the main influence factor in gushing. Using a pressure and temperature controlled measurement cell equipped with a high speed camera we investigate the mechanism of bubble formation resulting in gushing beer. The experimental work is complemented by mathematical modelling and numerical simulation of multiphase mass transfer based upon the Lattice Boltzmann Method. Contact

The aim of the research project is the optimization of a drying process for foods with supersaturated steam. For this purpose, a measuring system and a fuzzy-based control system based on it are being developed. The product condition measured in real time enables a new control concept, which automatically guarantees a dynamic drying process and thus a high homogeneity of the product, even with fluctuating material properties (e.g., moisture content or structure). Contact

Development of a fermentation management system to achieve an accelerated and reproducible fermentation process

This project is the first to develop a method for monitoring and targeted control of the fermentation process (fermentation management). The monitoring of the fermentation activity via ultrasonic measurements allows a targeted control of the fermentation process so that the yeast can be run under optimal fermentation conditions. Contact

Pulsating cleaning of membrane filter presses – In-situ cleaning of membrane filter presses via sensor controlled and demand-oriented automation

Cleaning and hygienic design of plants for the beverage, food and pharmaceutical industry are essential for hygienic and safe production cycles. However, filter media are still lagging behind these standards due to fine and hard to clean surfaces. In this project, a cleaning unit with a pulsating nozzle lance and an optical camera unit for suitable residue analysis is developed. Via an interface, the optical sensor communicates with the cleaning unit in order to demonstrate insufficient cleaned areas. This combination affords an optimized and on-demand cleaning concept. Exemplary, the research project works on a membrane filter press, which is used in mash separation. Contact

The aim of this project is the realization of a self-monitoring sensor network based on swarm intelligence. Particle Swarm Optimization (PSO) is used as a swarm algorithm. The intelligent sensor network will be able to detect faulty sensors and signals via multivariate linear and non-linear model approaches in comparison with other measured values and existing process information and to replace faulty sensor readings. Contact

The REIF research project investigates the potential of artificial intelligence to optimize the planning and controllability of food value creation. The aim is to establish an AI ecosystem that integrates stakeholders at all stages of the value chain in such a way that food waste can be reduced sustainably and holistically with the help of artificial intelligence. Further information can be found at: ki-reif.de. Contact

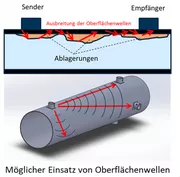

The ongoing automation of production plants requires the provision of cleaning concepts that can be monitored and controlled with inline-capable sensors. The aim of the project is to determine the cleaning success of pipelines inline on the basis of surface waves and to optimize the cleaning in place processes on the basis of the signals received. Contact

Drying in automated pasta production – Energy-efficient drying based on local substance-adaptive process intensification using the example of the automated production of pasta

Thermal drying with flowing air is one of the most important preservation methods in the production of pasta. The drying process lowers the water content, the reduced water activity inhibits the growth of spoilage microorganisms and the activity of enzymes. Due to the current construction of dryer systems, process inhomogeneities occur. Edge areas of food are subjected to excessive thermal stress, while core areas may contain moisture. The inhomogeneities are detected by screening along the drying channel width using a novel, non-invasive multi-sensor, which optically determines both the product moisture content using NIR measurement technology and the surface temperature and color of the product. With the help of CFD simulations, insights into the drying process are to be gained in order to produce and optimize a novel drying channel. Thanks to this sensor technology, the new dryer construction is able to dry the product specifically with steerable nozzles. In this way product damage can be avoided by over-drying while reducing the energy consumption. Contact

A central process step in the production of grain-based baked goods is the kneading process. Errors that already occur in dough production have an effect on the end product quality. The monitoring of the dough quality and the estimation of the expected end product quality is carried out by measurements in the rheometer. However, the samples must be taken from the process and are not always representative. In the course of the research project, the surface properties of the dough are to be detected by means of laser scattering, and from this the rheological characteristics are determined in real time using a developed model. Contact

Within the Lab Glasses project, a functional smartglasses demonstrator for the laboratory environment is being developed, which will make working more efficient by combining suitable hardware components, data storage methods, interaction modules and augmented reality. The following main functionalities are to be implemented: Display of context-relevant safety instructions, interaction of laboratory staff with laboratory equipment, more efficient documentation, display of standard operating procedures. Contact

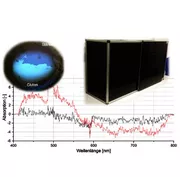

In this research project a novel approach to the evaluation of flour and dough properties is developed by a spectral approach. For this purpose, information of flours and doughs in the ultraviolet and visible light range as well as in the near infrared range is recorded by means of camera systems and correlated with the gluten properties. The results are intended to demonstrate a new approach to real-time, non-invasive flour quality measurement. Contact

Development of a level measurement technology for the precise and automated detection and monitoring of even small levels

The level measurement of very small amounts in gas cylinders or bioreactors leads to measurement errors with conventional systems. In this project an ultrasound-based measuring system for the determination of filling levels is developed, which guarantees a sufficiently high measuring accuracy even at lowest fill levels. This novel measuring system is developed in a first step as an example for the level measurement of gas cylinders for the operation of forklift trucks. As a result, gas cylinders no longer have to be changed to suspicion – and often with residual contents – as was previously customary. Contact

Monitoring the fermentation process by means of ultrasound – Developing a fermentation management to achieve an accelerated and reproducible fermentation process

The aim of this project is to control the fermentation process so that the yeast works at the optimum of its catabolic activity. Using an ultrasound-based method developed in a previous project, yeast fermentation activity is determined by extracting the medium. In combination with fuzzy logic control, the process parameters of the fermentation are adjusted with regard to an optimal metabolic activity. This should improve the reproducibility of the process and speed up the fermentation process itself. Contact

Spray Drying - Improving the performance of the CIP (Cleaning in Place) process in spray drying towers based on ultrasonic fouling detection

One of the most demanding milk spray drying challenges is sensor-based real-time cleaning status determination. Conventional techniques which have hitherto been used for fouling detection require constructive adaptation of the spray-drying towers. For this problem, a novel ultrasound-based measuring principle is developed, which distinguishes itself from the existing methods especially by its non-invasiveness and real-time capability. The real-time fouling measurement makes it possible to make the cleaning cycles dynamic and to shorten set-up times. Contact

Pore size distribution in biscuit foams – Optimization of the pore size distribution of grain-based foams for the production of fine baked goods

In this research project, a method is developed which detects the foam structure of grain-based foams in real time using ultrasonic measurements. The aim is to monitor the formation of pores during the manufacturing process with a new ultrasound-based measurement method. Furthermore, a new foam structure variable is established, which maps the number and size of process-relevant pores in real time. Through these measurements, conclusions can be drawn on the technological controllability of the processes. Contact

Volumetric ceramic burner – Systematic investigations on the application qualification of an innovative oven technology with a volumetric ceramic burner (VKB) and adjustable wavelength spectrum as well as high control dynamics and energy efficiency

As part of this research project, in cooperation with the LSTM Erlangen, a new heating technology – volumetric ceramic burner (VKB) – was qualified for the use in the baking industry. For this purpose, baking tests were carried out using 500 g wheat breads A thermographic method was used to investigate the interior of the oven and the baked goods surface (heat radiation, thermal bridges, thermal gradients). Thus, the radiation behavior of the furnace and the products was determined, which was used to simulate the baking process. The results showed that the thermographic data could be processed using image processing, allowing products to be evaluated in real time. This research project qualified a new heating technology for the industry. Contact

Intelligent control – Development of an intelligent control system for process optimization of thermal food processing by means of digital image processing and experience-based control

In this research project, the development of an optical measuring system and based on that a fuzzy-based control system for the fermentation process was carried out. The visual data were determined on the basis of the current state of the dough and its development. The process was adjusted by means of a fuzzy-based control system, which led to high-quality baked goods despite external disturbances. Despite fluctuating raw material and processing qualities as well as forced error operations, this system has been able to achieve a high product quality of the dough pieces. Contact

Yeast propagation and filtration process – Knowledge-based process intelligence – new paths to stable bioprocesses; subproject: production of active yeast and investigation of the influences on the further process chain in beer production

In this project, the yeast propagation and the filtration process of beer will be equipped with newly developed online sensors in order to generate knowledge about the processes as well as to regulate the process. First, the critical process parameters are identified and their influence on the final product quality of beer is examined. Furthermore, the focus is on the establishment of process corridors for monitoring product quality. Contact

Food packaging - Process-induced changes in physical packaging properties as a marker for high-pressure and temperature treatment of packaged food

In this project, a laser-based measuring system for the traceability of high-pressure treated packaging material was developed. The thermally pressure-modified microstructures exhibited altered laser reflection patterns, which were successfully detected and evaluated using optical sensors. Contact

This project dealt with the characterization of heat and mass transfer phenomena in foams. The focus was on the influence of microstructure and material properties. In addition, the flavor release to the environment was modeled using the Lattice-Boltzmann method. Contact

NIR fingerprinting – NIR fingerprinting as a measuring method for the assessment of malt batches according to their cleanability

Lautering is a time-critical process when processing beer. Furthermore, this method is highly dependent on the quality of the used resource malt. Therefore, the maltes used must meet tight specifications to prevent refining problems. Quality analysis of malt has been the subject of various scientific investigations for years, which has led to the establishment of a multitude of descriptive parameters. However, this parameter lacks the ability to significantly predict. Therefore, in this work by means of near-infrared spectroscopy (NIR) fingerprinting a method was developed, which is used for the characterization and classification of malt batches. Contact

Minimal Processing – Minimal processing in automatic meat processing chains – physical imaging for structure and texture recognition in meat processing

In the absence of suitable automation possibilities, the fine separation of meat is mainly done manually. In order to control the regulation of positioning and cutting, two modern imaging techniques are combined. The first method is a stereo camera system with connected digital image processing, which detects the spatial position and geometry of the meat parts, the second method is an ultrasound system, which analyzes the internal structure of the meat and bone structures. Contact

Yeast Fermentation – Process-suited ultrasonic measuring system for monitoring and controlling concentrations of relevant components in industrial yeast fermentation processes

Determining extract and alcohol concentrations is essential for optimizing production, ensuring product quality, and reducing energy and resource costs. These measurements form key figures describing the production progress in the fermentation industry. For this purpose, an ultrasound-based measuring system was developed and its signals were evaluated by means of multivariate modeling methods. By that, a process-suited measuring system was available to holistically monitor industrial yeast fermentation processes. Contact

Fouling / Cleaning in Heat Exchangers – Ultrasonic based measurement system to track fouling in heat exchangers and validate cleaning success

Deposits in heat exchangers are the limiting factor in milk processing. They lead to contamination and thus reduce the heat output of the heat exchanger. The resulting daily cleaning process is costly (plant shutdowns, water, energy, detergents) and significantly affects the cost-effectiveness of the system. Thanks to the developed acoustic early detection, cleaning intervals are optimized and cleaning agents are saved. Contact

Yeast management – Development of a yeast management system with yeast propagation and vitalization for automated control

For the automated monitoring and control of the aerobic biomass production, a yeast management system was developed as part of this project, which combines the processes yeast propagation and vitalization. Through the integration of suitable measuring technology for the determination and monitoring of relevant process parameters as well as an adapted control system based on a virtual expert system, a dynamic process management was created, which allows a targeted yeast production for the subsequent fermentation and a revitalization of harvest or plant yeast for the return to the process. Contact

Getreidevorratsschädlinge wie der Kornkäfer (Sitophilus granarius) oder der Getreidekäfer (Oryzaephilus surinamensis) verursachen jährlich erhebliche wirtschaftliche Schäden in Landwirtschaft und weiterverarbeitenden Industriezweigen. Im Rahmen des vorliegenden Forschungsvorhabens wurde ein praxistaugliches Gerät zur automatischen akustischen Früherkennung von Getreideschädlingen entwickelt und etabliert. Kontakt

Hartweizen – Qualitätsbewertung von Hartweizen, Hartweizengrieß und Hartweizenprodukten durch die Auswertung digitaler Bilder

The aim of this research project was to establish an automated quality assessment system for durum wheat grains, semolina and pasta products using digital image processing techniques. The development of the automated quality control process will help reduce human interference in quality decision making, reduce the time required for this process, and increase the accuracy of the evaluation process. Contact